Every packaging tells a story, from the tape that holds it together to the branding imprinted on it. The choice that is paper tape vs. plastic tape has great implications for businesses, whether it’s how customers perceive a product or how the tape holds up in the construction business; paper tapes have become so reliable that they are getting increasingly popular in industries such as aerospace. In this blog, we will delve into what box packaging tape is best for your business, considering factors from the strength and reliability of the tape dispenser technology, ensuring that your business finds the perfect packaging materials.

How Do Paper Tape and Plastic Tape Differ?

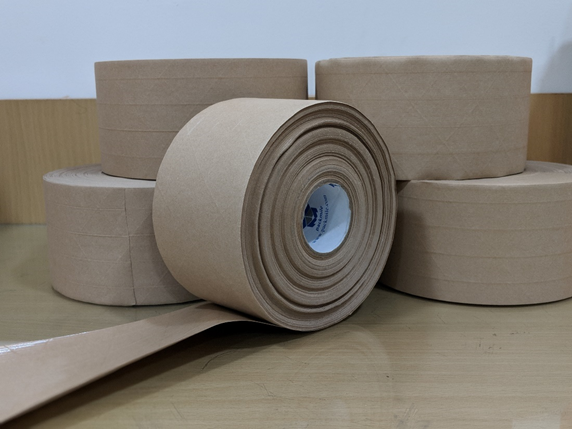

Paper tape is made from different types of paper, like flatback paper, and adhesives such as silicon adhesives. Used in industries such as construction and automobile, they are strong, durable, and light; made from wood-based paper, they are eco-friendly and decompose, starkly contrasting to plastic tapes. Plastic tape is typically made from polypropylene or PVC, which are synthetic materials.

While plastic tape is generally more resistant to moisture, etc., paper tape can be lined up with different materials, such as fiberglass. Paper and plastic tape have adhesive backing to ensure proper surface adhesion.

Paper tape is biodegradable, recyclable, and compostable, making it a sustainable choice for businesses aiming to reduce their environmental footprint. Plastic tape, being non-biodegradable, poses challenges in terms of disposal and recycling.

Paper packaging tape prices are surprisingly economical for businesses, enabling modern businesses to adopt an eco-friendly taping solution without breaking the bank.

Why is Paper Tape Gaining More Popularity Among Businesses?

The paper tape market is booming, accelerating at a CAGR rate of 4.6% between 2023 to 2033, and valuing 5.6 Billion USD.

In recent years, paper tape has gained significant popularity among businesses for various reasons. This is especially true in the automobile industry because of its reliability and lightweight nature. Let’s detail the advantages, exploring their importance, benefits for business owners, practical applications, and conversion into the customer experience.

Environmental Impact:

The environmental impact of packaging materials has become a pressing concern for businesses and consumers alike. Paper tape stands out as a more eco-friendly option compared to plastic tape. Its composition primarily consists of kraft paper, a biodegradable and recyclable material derived from wood pulp. Businesses can use paper tape to demonstrate their commitment to sustainability and reduce their carbon footprint. This aligns with the growing demand for environmentally responsible practices and can help businesses attract eco-conscious customers. Moreover, opting for paper tape showcases a dedication to reducing waste and landfill accumulation, positioning the business as a responsible and environmentally conscious brand.

Strength and Durability:

Although paper tape may not possess the same inherent strength as plastic tape, it still offers sufficient durability for many packaging applications. This makes it a viable option for businesses, especially in industries like construction, where packages often require additional reinforcement. Paper tape can securely seal boxes, providing reliable protection for the contents during transit. Its strength and durability in construction packaging demonstrate its practicality and effectiveness in demanding environments. Business owners can confidently use paper tape to ensure their products arrive safely and intact at their destination.

Customization and Branding:

Packaging is a powerful tool for branding and creating a memorable customer experience. Paper tape allows for customization through printed designs, logos, or messages. This allows businesses to enhance their brand identity and differentiate themselves from competitors. Customized paper tape adds a professional and cohesive touch to packaging, increasing brand recognition and creating a positive impression. Customers appreciate the attention to detail and the personalized touch of packaging, as it conveys the business’s commitment to delivering a unique and branded experience.

Cost-Effectiveness:

Cost considerations are crucial for businesses across industries. Paper tape offers a cost-effective alternative to plastic tape. It is often competitively priced and provides good business value, especially considering the length of tape per roll and overall packaging costs. The affordability of paper tape allows businesses to meet their packaging needs without compromising their budget. This is particularly advantageous for companies with high-volume packaging requirements, as it helps optimize their expenses and contribute to their bottom line.

Customer Satisfaction:

Customers are increasingly drawn to businesses prioritizing sustainability and offering eco-friendly products and packaging. Using paper tape, business owners can meet the growing demand for environmentally conscious solutions. The eco-friendly nature of paper tape resonates with customers who seek to support brands that share their values. Additionally, paper tape’s natural and rustic appearance adds a charming and authentic touch to the packaging. It creates a visually appealing unboxing experience that customers find engaging and delightful. Combining eco-friendliness and stylish packaging contributes to overall customer satisfaction, enhances brand loyalty, and increases the likelihood of positive word-of-mouth recommendations.

Lightweight:

Industries with weight-sensitive applications, such as aerospace, greatly benefit from the lightweight nature of paper tape. It allows businesses to reduce the overall weight of packaging materials without compromising strength or reliability. Using lightweight packaging materials, including paper tape, contributes to fuel efficiency during transportation, cost savings, and improved sustainability. Business owners in the aerospace industry can rely on paper tape to meet stringent weight requirements while ensuring the secure packaging of their products. This lightweight advantage allows for optimal performance and efficiency, making paper tape an ideal choice for such industries.

Compatibility with Different Materials

Paper box packaging tape is compatible with various materials, making it a versatile choice for various industries and packaging needs.

For example, paper tape is a reliable sealing solution in the construction industry, where packaging requirements often involve heavy and bulky materials. It adheres securely to cardboard, wood, metal, and plastic, providing robust protection during transportation and storage. Whether sealing boxes of construction tools, hardware supplies, or building materials, paper tape offers dependable adhesion and strength, ensuring the contents remain secure and protected.

In the e-commerce and retail sectors, businesses deal with diverse packaging requirements, ranging from fragile items to clothing, electronics, and more. Paper tape works well with various packaging materials commonly used in these industries, such as corrugated cardboard, kraft paper, and lightweight plastics.

Challenges with Traditional Plastic Tape

Here are some common challenges associated with traditional plastic tape:

Environmental Concerns:

One of the significant challenges with traditional plastic tape is its negative environmental impact. Plastic tape is typically made from materials like polypropylene or PVC, which are non-biodegradable and pose challenges in disposal and recycling. With increasing awareness of sustainability and the demand for eco-friendly practices, businesses may face criticism or backlash for using non-recyclable materials, impacting their brand reputation and customer perception.

Limited Customization:

Plastic tape offers limited options for customization compared to other packaging solutions. While it may be available in different colors or patterns, the ability to add personalized branding, logos, or messages is often limited. This limitation restricts businesses from leveraging packaging as a marketing tool and creating a unique and memorable unboxing experience for customers.

Tape Dispenser: A Helping Hand

A paper tape dispenser is an invaluable tool that significantly enhances packaging, particularly when handling high volumes of packaging materials. It offers several advantages that make it a helping hand for businesses seeking efficiency and a seamless packaging experience.

Improved Efficiency:

A tape dispenser streamlines the packaging process, allowing faster and more efficient sealing of boxes or packages. It eliminates the need to manually handle and cut individual pieces of tape, saving valuable time and reducing labor costs. With a tape dispenser, packaging personnel can apply the tape smoothly and swiftly, ensuring a consistent and professional seal with minimal effort.

Enhanced Precision:

Tape dispensers provide a precise and controlled application of the tape, resulting in neater and more secure seals. The dispenser’s mechanism allows for accurate positioning and alignment of the tape, reducing the chances of misalignment or uneven application. This precision ensures that packages are properly sealed, reducing the risk of damage or tampering during transit.

Ergonomic Design:

Modern tape dispensers are designed with user comfort in mind. They feature ergonomic handles and grips, reducing strain on the hand and wrist during repetitive tasks. This ergonomic design promotes employee well-being, minimizing the risk of fatigue or repetitive stress injuries. With a comfortable and user-friendly tape dispenser, packaging personnel can maintain productivity and efficiency throughout the packaging process.

Handling High Volumes:

A tape dispenser is indispensable for businesses dealing with high volumes of packaging. It can handle continuous and repetitive sealing tasks with ease. By eliminating the need to cut tape manually, packaging personnel can maintain a steady workflow and handle large quantities of packages efficiently. This capability is particularly beneficial during peak seasons or when faced with tight deadlines.

Consistency and Professionalism:

A tape dispenser ensures consistent tape application, resulting in a professional and uniform appearance across all packages. With precise tape lengths and controlled application, businesses can present a cohesive and aesthetically pleasing packaging experience for their customers. Consistency in tape application also reflects attention to detail and professionalism, enhancing brand reputation and customer satisfaction.

Waste Reduction:

Tape dispensers often include features that minimize tape waste. Some models offer adjustable tape lengths, allowing for customization based on package sizes and requirements. This reduces unnecessary tape consumption, saving costs and reducing environmental impact. Additionally, tape dispensers facilitate easy tape roll replacement, ensuring all tape on the roll is utilized efficiently and minimizing waste.

To Conclude

As we wrap up the ultimate showdown between paper tape and plastic tape, it’s clear that businesses seeking reliable taping solutions are gravitating towards the eco-friendly and versatile nature of paper tape. Its compatibility with different materials, strength, cost-effectiveness, and ability to create a personalized packaging experience has made it a frontrunner in the competitive world of packaging. By embracing paper tape, businesses can not only meet their packaging needs but also contribute to a greener and more sustainable future.

Make the switch to sustainability with Packmile’s reliable paper tapes.

Leave A Comment