CORMTM

Corrugated Box Recycling Machine

Convert waste/unwanted boxes to useful packaging material used as packaging fillers for wrapping or void filling so that your products are protected during transit in a very short-time; thus saving on procuring additional packaging materials. Give your boxes a second-life!

GO GREEN, REDUCE COSTS AND SAVE THE ENVIRONMENT!

Reduce your packaging costs

Save on Cardboard Disposal cost

Low cost

Low maintenance

Safe and User-Friendly

No pre-cutting required

Perfect for void fill & wrapping

Small Footprint

Dust extraction outlet built in

TURN UNWANTED WASTE BOX INTO

SOFT, FLEXIBLE USEFUL MATERIAL

AND SAVE ON PACKAGING!

The new energy-efficient packaging machines

Energy-efficient drive technology thanks to the use of a frequency converter. 30% energy saving with same output!

High motor torque even at low speeds

High dynamics

High degree of efficiency

Low-maintenance

And above all energy efficiency!

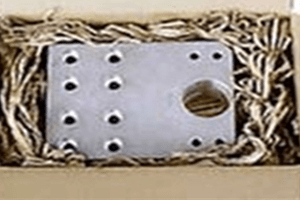

CORMTM Machine

CORMTM Machine details

TECHNICAL SPECS

| MODEL | CORM 320 | CORM 422 |

|---|---|---|

| CUTTING WIDTH | 320 MM | 422 MM |

| CARBOARD THICKNESS (INDIA MEASUREMENT) | UPTO 5PLY | UPTO 7PLY (SOFT BOARD) |

| PRODUCTION OUTPUT | 2-3 M³/H | 4-6 M³/H |

| WORKING HEIGHT | 870 MM | 870 MM |

| THROUGHPUT RATE (SPEED) | 12 M/MIN | 13 M/MIN |

| MOTOR CAPACITY | 0.75 KW (3 PH) | 1.5 KW (3 PH) |

| MAIN VOLTAGE | 200-400 V | 200-400 V |

| 50-60 HZ | 50-60 HZ | |

| DIMENSIONS HXBXT (MM) | 980X660X660 | 980X660X660 |

| WEIGHT | 110 KG | 125 KG |

QUALITY PARAMETERS

| * Makes 2 formats – Wave and Mat. No other machine can do that. “Wave” is the most widely used cushioning & void-filling material used for packaging. |

| * The blades are of the highest German made quality – some of them don’t require any changes for next 10yrs (depends on usage) |

| * Automatic cutting is done. No additional preliminary blade is required. |

| * Space-saving storage of cardboard boxes and just-in-time production of packaging materials help in reducing storage costs. |

| * In-built dust extraction outlet is provide to connect the vacuum cleaner to extract dust that generates from recycling boxes. |

| * In case the boxes are stuck while processing, there is a button to “reverse” the boxes. This enables the feeder take out the stuck material |

SAFETY FEATURES

| * Machine is designed with the highest safety weightage in mind. When feeding the Packer’s fingers will not get into the space where the blades are rotating. Thus, preventing any mis-happenings/injuries. |

| * If the machine overheats, it will automatically switch off. A button for the same is provided. It will restart in a few minutes after cool down |

| * Emergency stop button (Red) is provided on all machines, in case the operator needs to stop to machine for Emergency reasons only. |

Comparison – Plastic vs Recycled Corrugated Box

OPERATIONS

| NARRATIVE | RECYCLED CARTON DUNNAGE | PLASTIC DUNNAGE |

|---|---|---|

| ECO-FRIENDLY, ENVIRONMENTAL CONSCIOUS |  |

|

| FREE COST OF RAW MATERIAL – SAVES ON COST |  |

|

| MORE CUSHIONING & PROTECTION |  |

|

| DO YOU HAVE TO BUY RAW MATERIAL? |  |

|

| INCREASES THE WEIGHT OF THE BOX |  |

|

| EASY TO OPERATE |  |

|

CUSTOMER EXPERIENCE

| NARRATIVE | RECYCLED CARTON DUNNAGE | PLASTIC DUNNAGE |

|---|---|---|

| EASY TO DISPOSE |  |

|

| RECYCLABLE & BIO-DEGRADABLE |  |

|

| CUSTOMER APPRECIATION (SINCE IT’S ECO-FRIENDLY) |  |

|

FAQ

What are the benefits of using a CORMTM machine?

Packmile’s CORMTM machine offers various benefits. It optimises carton size, reduces shipping costs, improves sustainability, enhances customer experience, and increases productivity, making it a valuable tool for businesses reliant on shipping and logistics.

Is it difficult to operate a CORMTM machine?

Operating a CORMTM machine typically requires some training, but it is designed to be user-friendly and easy to operate once familiarised with the system. The difficulty level may depend on the specific machine and software used, as well as the user’s experience with similar technology.

Usage

WRAPPING