We’ve heard about Paper Tapes lately, and they’re becoming a more commonly used packing element in business. With the Adhesive Tapes Market set to hit $77.62 billion by 2027, a lot of companies are already opting to switch to Paper Tapes, also called kraft paper tape, right off the bat due to its unique properties and the increased margins owing to the switch. Without a doubt, if a product is eco-friendly and cost-effective, the results usually indicate a strong trend growing in favor of its usage – and this is just the case with using Paper Tape for Packaging.

As we know, Paper Tapes are uber-useful and have become quickly recognized and given prominence while considering packaging processes for various types of businesses. Within the Paper Tapes world, there are mainly two that are considered for large-scale purchase, namely:

Water-Activated Paper Tapes and Self-Adhesive Paper Tapes.

Both of these adhesive paper tapes are considered efficient and modern ways to pack and seal, although the issue remains, which one is a better, eco-friendly, and more effective choice for your business?

Water-Activated Tapes (WAT)

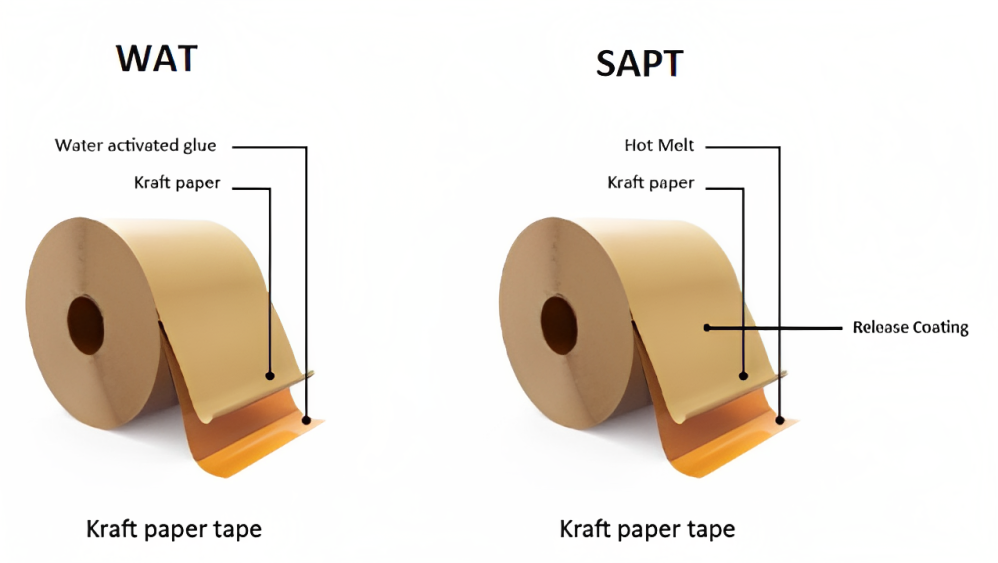

Water-Activated Paper Tape, also called gummed paper or gum paper tape, is a starch-based adhesive paper tape made of completely natural, renewable, and biodegradable adhesive. Water-Activated Paper Tape feels dry and is non-adhesive until the starch-based adhesive comes in contact with water – in which case it immediately becomes super-sticky and can be applied onto the intended surface, such as boxes or envelopes, for the ultimate sealing. Popularly, there are two variants: Non-Reinforced WAT and Reinforced WAT – the reinforced fiberglass liners enable Water-Activated Tapes to secure even the heaviest of boxes and prevent pilferages.

Research has shown us a definite 20% increase in packer productivity when using Water-Activated Tape and a Paper Tape Dispenser. Since Water Activated Tapes are 100% eco-friendly tape and biodegradable, they also tend to be quite rewarding on the pocket as well as on the conscience.

Advantages of Water-Activated Tape (WAT) for Sustainable Packaging:

- Greener Alternative: WAT is made with a glue that is 100% biodegradable, contributing to a reduction in landfill waste. WAT offers a sustainable alternative to conventional plastic-based tapes, with biodegradability, recyclability, and compostability. Additionally, WAT breaks down naturally over time, minimizing its impact on the environment.

- Recyclable: The kraft paper material used in WAT production is widely accepted in recycling programs, promoting a circular economy.

- Easy removal: WAT can be easily removed from packaging materials, allowing for conveniently recycling cardboard or paper components.

- Cost-effective: Although the initial cost may be slightly higher, WAT’s secure bonding reduces the need for additional tape layers, optimizing tape usage and leading to cost savings over time.

- Demonstrates commitment: Choosing WAT demonstrates a business’s commitment to sustainable packaging and environmentally conscious practices.

- Reliable and secure: WAT provides a reliable sealing solution while minimizing environmental impact.

Self-Adhesive Paper Tapes (SAPT)

Self-Adhesive Paper Tape is quite similar to Plastic, a.k.a BOPP Tapes. They are made with polymer-based release coating applied on the top layer of the kraft paper tape and a hot melt adhesive applied on the bottom layer. This multi-layered substrate tape is advertised and marketed to be an eco-friendly tape replacement for plastic tapes, although that is quite far from the truth. They are made with synthetic adhesives that are not recyclable, hence, like plastic tapes.

The common ploy with marketing SAPTs is everywhere: Advertise them as eco-friendly because they are, after all, just ‘Paper Tape’, yet conveniently not mention ‘Release Coating’ & ‘Hot Melt Glue’ and its side effects.

Release Coating or lamination made with either Linear-Low-Density-Polyethelene (LLDPE) or Silicone for winding off the roll so that the hot melt adhesive doesn’t stick to the paper. It’s an important process to make the tapes.

Hot Melt Adhesive, or Hot Glue, is the name given to any polymer-based glue applied in a molten state. The primary polymers used in hot melts are ethylene-vinyl acetate (EVA), polyolefins, polyamides and polyesters, styrene block copolymers, polyethylene, and ethylene-methyl acrylate (EMA) or ethylene n-butyl acrylate (EnBA). Along with the polymers, SAPT is a thermoplastic material made of additives, stabilizers, and pigments used extensively in plastic tapes.

Here are a few stark differences between Water-Activated Tapes and Self-Adhesive Tapes:

| Narrative | Water-Activated Tapes (WAT) | Self-Adhesive Paper Tapes (SAPT) |

| Adhesive | Contains starch-based adhesive such as Potato, Tapioca | Contains polymer-based coating, hot-melt glue adhesive |

| Eco-friendly | 100% Biodegradable and Environment Friendly | Not Recyclable/Biodegradable. Results in Pollution |

| Activation | Requires only water for activation | Pressure Sensitive-activated |

| Conditions of Usage | Resistant to Extreme Temperatures | Influenced by Extreme Temperatures and Dust |

| Strength | Built for strength and offers superb bond. | Lower Peel strength hence not a strong bond |

| Pilferage | Anti-pilferage, long lasting and highly secure | Can be tampered and pilfered due to weaker bond |

| Duration | Can securely hold for long durations | Can be used for short runs |

According to a study, not all hot melt adhesives allow easy paper recycling. This is exactly the result of “Greenwashing” because with SAPTs, only the paper is recyclable, not any other substrate. This self-adhesive tape is multi-layered material that is extremely difficult to recycle and hence not eco-friendly!

WAT has been in existence for many years. It’s been used in various established and robust geographies with strong supply-chain operations. It is slowly transitioning into large eCommerce and developing countries because of its proven technology and benefits. Industries such as textiles, electronics, and products shipped worldwide have gained immensely. With the rising consumer awareness and political and regulatory shift towards sustainability, switching to WAT is imperative.

The differences only show how WATs and SAPTs have their own uses and purposes, albeit with the Water-Activated Tape having a significant edge over the Self-Adhesive Tape.

How to Use Water-Activated Tape?

Water-activated tape can be used manually or through an automatic dispenser, however, it is advisable to use a water-activated tape dispenser to reduce the fuss and time taken during the packaging process.

Using a water-activated tape dispenser simplifies the process of sealing packages. Follow these steps to achieve seamless packaging:

- Load: Load a roll of water-activated tape onto the dispenser, ensuring it is securely in place.

- Measure & Cut: Determine the desired length of tape needed for your package and use the dispenser’s cutting mechanism to obtain an accurate cut.

- Moistening: Use a wet sponge to moisten the adhesive side of the tape or you could use a tape dispenser for ease of operation.

- Application: Apply the moistened tape to the package, gently pressing it down to promote proper adhesion.

- Activation: The water-activated adhesive will activate upon contact with moisture, securely sealing the package.

- Drying: Allow the tape to dry naturally, usually taking approximately 15 to 60 seconds, depending on environmental conditions.

- Reliable Seal: Once dry, the water-activated tape forms a robust and tamper-evident bond, ensuring the contents of your package are protected during transit.

Utilizing a water-activated tape dispenser can streamline your packaging process, enhance efficiency, and achieve reliable sealing for your valuable shipments.

Frequently Asked Questions

1. How long does it take for water-activated tape to dry?

The drying time for water-activated tape typically ranges from 15 to 60 seconds, depending on the specific brand and environmental conditions.

2. Can water-activated tape be customized with logos or branding?

Yes, the water-activated tape can be customized with logos or branding through printing options available from certain manufacturers.

3. What are the different types of water-activated tape available?

The different types of water-activated tape include:

RWAT: Reinforced WAT Paper tape (with fiberglass strands for added strength),

WAT: Non-reinforced tape (suitable for lighter packaging, typically under 10 kgs of box weight). Both these types of tapes can be printed for better customer branding. These tapes are biodegradable paper tapes which makes them eco-friendly and sustainable.

4. Can water-activated tape be used for heavy-duty packaging?

Yes, water-activated tape can be used for heavy-duty packaging due to its strong adhesion and durability, making it suitable for secure sealing in demanding applications. RWAT can box pack weight from 10 kgs - 40 kgs.

5. Where can I purchase water-activated tape?

You can try Packmile’s water-activated paper tape, which is highly durable and easy to use for any type of packaging. This is biodegradable paper tape, which provides high strength and is safer for the environment.

Comments are closed.

Recent Comments